10

Inventory of Innovative Indoor Smoke

Alleviating Technologies in Nepal

concentration level of RSP, CO, HCHO for ICS was 3000

µg/m3, 10.8 ppm and 0.6 ppm for ICS respectively. Ried

et al. (1986) compared the concentration level of CO

and TSP of traditional stoves without chimneys and ICS

with chimneys in middle hill districts of Nepal. The data

in table 3.1 clearly depicts that exposure of RSP, CO and

TSP is significantly reduced with the use of ICS compared

to traditional ones.

In order to reduce IAP, construction of better ventilated

rooms is also equally important along with improved

stoves and fuels. According to a comparative study

conducted by Holly F. Reid, Kirk Smith and Bageshowri

Sherchan, the mean personal exposure to TSP in agena

(traditional cooking stoves) and ICS was 3920 µg/m3

and 1130 µg/m3 respectively. Similarly, mean personal

exposure to CO in traditional and ICS was 380 ppm and

67 ppm respectively, which implies that ICS reduces

indoor TSP and CO concentration by 71 and 82 per cent

respectively (Raut 2006).

HHs were relieved from problems and diseases caused

by smoke. The overall positive impact on health reduced

the medical expense by 75 per cent. The average ICS

operating hours in these districts were 3.7 hours (TRUST

2004). The cost of useful heat per MJ (considering 1 kg

of fuel wood = 16.5 MJ) in ICS ranges from NRs. 0.37 to

0.44 compared to NRs. 0.95 in traditional iron tripod

stove. Likewise, for ICS users including opportunity cost,

the cost of useful heat per MJ ranges from NRs. 0.37 to

0.44 compared to NRs. 0.68 to 0.78 when using kerosene

(SECCON 2000). Field test in Dalchoki VDC of Lalitpur

district further proved that use of ICS saved 20 - 25 per

cent fuel wood compared to traditional stove (WP/ IDC/

Sulpiya 1997 cited by SECCON 2000).

3.2 Mud-brick improved cooking stoves

During the dissemination of ICS, NICSP mainly focused

on developing public awareness on health impact caused

by IAP. There is no direct subsidy for ICS users. ICS users

receive training, promotional and information materials

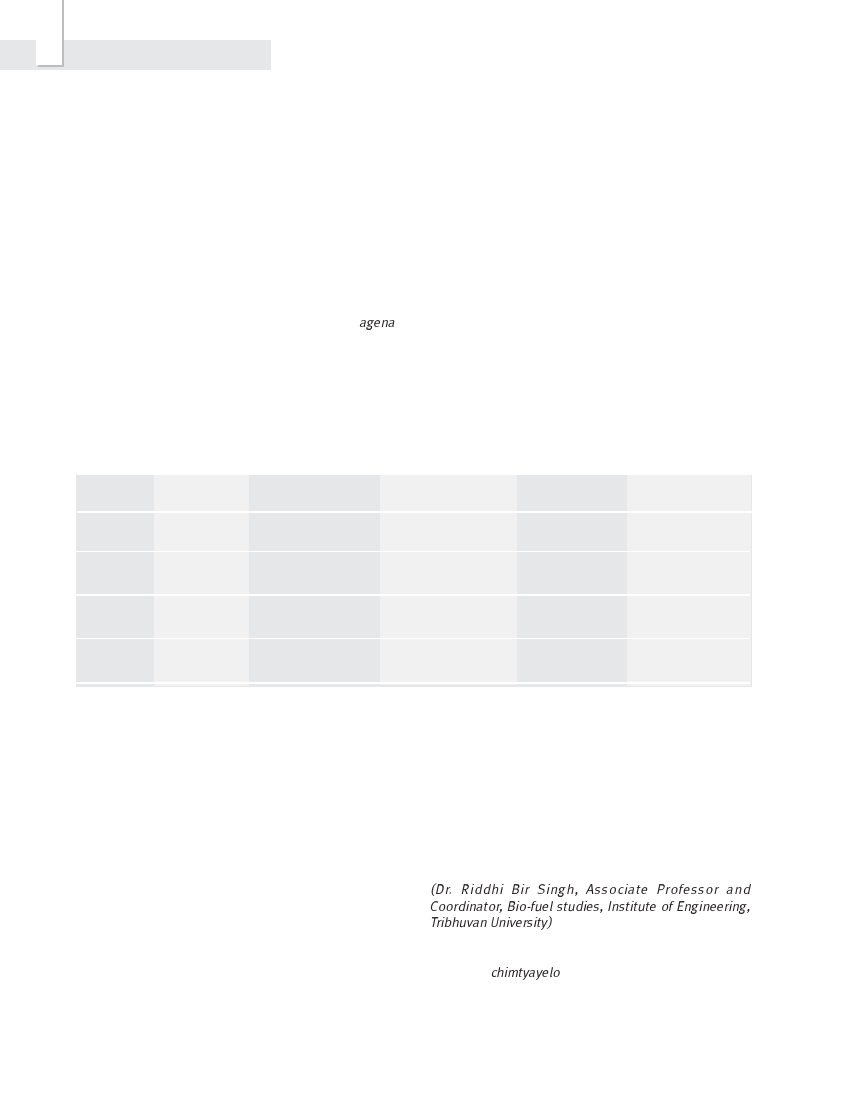

Table 3.1: Comparison of CO and TSP in traditional and improved stoves

Study

location

Gorkha

Pollutants

CO

TSP

Exposure on

traditional stove

280 ppm

3170 µg/m3

Exposure on

improved stove

70 ppm

870 µg/m3

Beni CO

TSP

310 ppm

3110 µg/m3

64 ppm

1370 µg/m3

Mustang

CO

TSP

64 ppm

1750 µg/m3

41 ppm

920 µg/m3

Bardibas

CO

TSP

82.5 ppm

8200 µg/m3

11.6 ppm

3000 µg/m3

Source: SECCON 2000 (cited from Sharma 1995)

% reduction

75

73

79

56

36

47

86

63

References

Reid 1986

Reid 1986

Reid 1996

Pandey 1990

The impact study report on effectiveness of ICS

programme in Doti, Dang, Kavre, Udaypur, Ilam,

Kathmandu, Syangja, Baglung, Surkhet, Sindhuli and

Dadeldhura revealed that 90 per cent HHs used two

potholes mud-brick ICS. In Dadeldhura, 48 per cent were

found using one pothole stove. Three potholes mud-

brick ICS were found sparsely in Sindhuli, Baglung and

Surkhet. About 65 per cent stoves were found near

window, whereas, 23 per cent were found near the door.

In Ilam, stoves were found separately placed in a shed.

The report also revealed the promoter’s vital role (70

per cent) in the adoption of ICS followed by their

neighbour’s inspiration (18 per cent). All users were

provided with the information on repair and maintenance

and 59 per cent were provided with user manual. As per

the expectation of ICS, 90 per cent reported saving time

(fuel wood collection and cooking time) and majority of

as indirect subsidy. The mud-brick ICS is installed by

trained ICS local promoters on request from the user as

per his/her preference - one, two or three potholes with

different sizes. The trained promoters are paid by end

users. The efficiency of traditional and mud-brick ICS

normally varies from 6 to 10 per cent and 12 to 20 per

cent respectively and the reasons for variation in

efficiency are deviation in construction of ICS from

design, and also the type and moisture content of fuel.

(Dr. Riddhi Bir Singh, Associate Professor and

Coordinator, Bio-fuel studies, Institute of Engineering,

Tribhuvan University).

The materials required to build the mud-brick ICS stoves

are - soil (chimtyayelo, i.e. sticky soil), rice husk, dung

and water. Soil, dung and rice husk are mixed in proportion

of 5:1:2 and water is added to make a paste. Dry sand or